DTF Printing Demystified: Every Little Thing You Required to Know About Direct-to-Film

DTF Printing Demystified: Every Little Thing You Required to Know About Direct-to-Film

Blog Article

The Future of Fashion: Exploring DTF Printing Modern Technology in the Textile Sector

Among these improvements, Straight to Movie (DTF) printing technology has actually arised as an appealing competitor, supplying unique capabilities and possibilities for designers and makers alike. This sophisticated printing approach has stimulated rate of interest due to its potential to transform conventional textile printing processes.

Advancement of Textile Printing

From the old people using techniques like block printing to the electronic revolution of today, textile printing has consistently pressed borders. As the craft spread to various other components of the world, brand-new techniques such as screen printing and roller printing arised during the Industrial Transformation, transforming the textile industry.

The introduction of electronic textile printing in the late 20th century marked a significant shift towards more flexible and sustainable printing techniques. The evolution of fabric printing showcases an abundant history of imagination, resourcefulness, and technological development in the globe of fashion and layout.

Benefits of DTF Technology

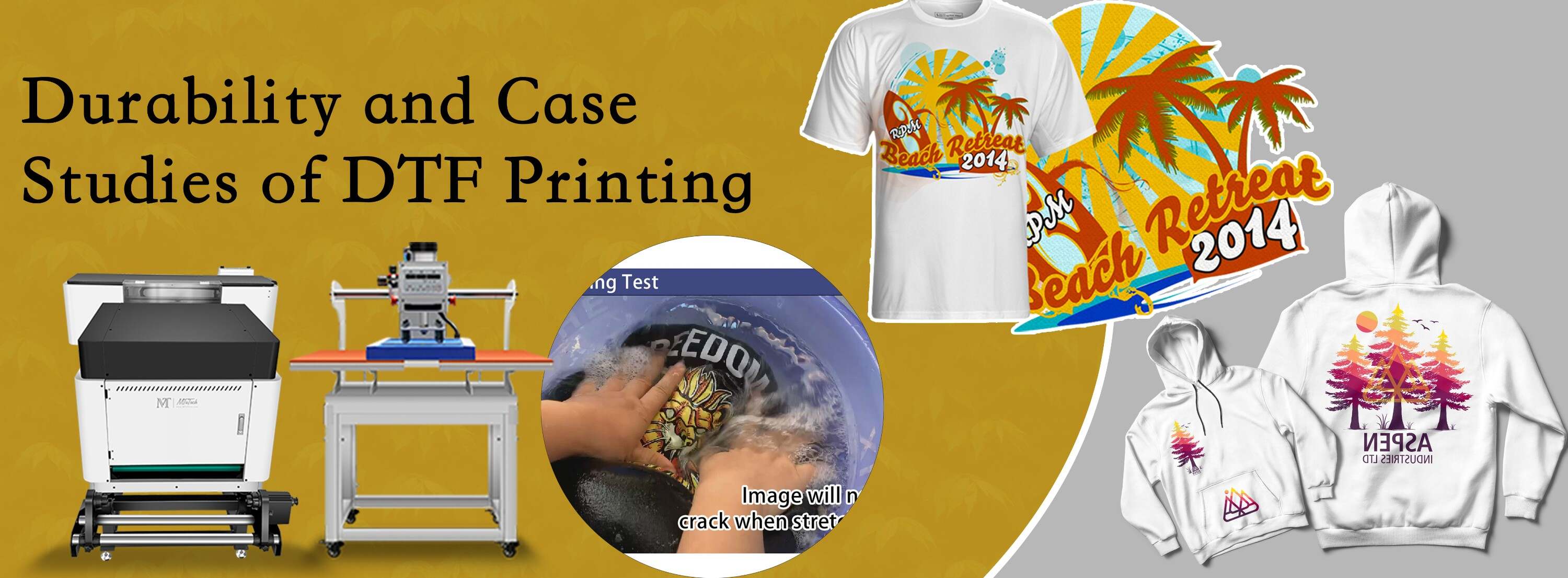

With the advancement of fabric printing techniques from ancient techniques like block printing to modern advancements such as digital printing, the intro of Direct-to-Fabric (DTF) innovation has actually considerably enhanced the performance and sustainability of textile printing processes. Among the primary advantages of DTF modern technology is its capability to straight print styles onto textile without the need for transfer documents, which minimizes waste and streamlines the production procedure. In addition, DTF printing enables greater shade vibrancy and information accuracy contrasted to standard techniques, making it possible for fabric manufacturers to produce high-quality and complex styles easily.

Additionally, DTF modern technology is understood for its flexibility, as it can be utilized on numerous kinds of textiles, consisting of natural fibers like woollen, silk, and cotton, along with synthetic materials such as polyester and nylon (DTF Printing). This flexibility opens up a large array of possibilities for makers and designers to experiment with various textures and products, resulting in even more ingenious and special products in the fashion business. Overall, the execution of DTF modern technology stands for a substantial advancement in fabric printing, providing numerous advantages that add to the future sustainability and creative thinking of the sector

Sustainability in Style Production

Emphasizing green methods is extremely important in modern fashion production, aligning with the expanding customer need for lasting products. In recent times, the garment industry has actually encountered increasing examination due to its substantial environmental impact, consisting of excessive water use, chemical pollution, and textile waste. As an action, several style brand names are currently including sustainable techniques into their production procedures to lessen harm to the environment.

Sustainability in style manufacturing encompasses various facets, such as making use of organic and recycled materials, decreasing energy consumption, implementing moral labor techniques, and advertising openness throughout the supply chain. Additionally, advancements in technology, like DTF printing, offer possibilities to additionally improve sustainability in textile manufacturing. This innovation allows exact printing on fabrics, decreasing ink waste and water use compared to typical printing approaches.

Design Freedom and Modification

In addition, DTF printing promotes this page personalization on a scale previously unattainable, permitting for personalized garments and one-of-a-kind items customized to specific preferences. Consumers can currently actively take part in the style process, producing garments that show their design and individuality. This personalization not only boosts the consumer experience but also promotes a feeling of exclusivity and individuality in a market saturated with mass-produced clothing. Overall, DTF printing modern technology changes the layout landscape in the textile industry, offering endless opportunities for creative expression and tailored style.

Influence On Supply Chain & Market Trends

DTF printing innovation in the textile sector is reshaping supply chain dynamics and influencing market fads with its performance and personalization capabilities. By making it possible for on-demand printing and eliminating the demand for big supplies, DTF technology improves the supply chain procedure. Producers can generate things Discover More as needed, lowering waste and storage expenses. This just-in-time production design likewise enables quicker response to market needs and patterns, leading to a much more dexterous and receptive supply chain.

Moreover, the personalization possibility of DTF printing technology is transforming the market trends in the fabric market. As an outcome, DTF technology is driving a shift in the direction of more customer-centric and innovative strategies within the textile market, forming the future of fashion.

Verdict

Finally, DTF printing innovation is revolutionizing the fabric industry by providing countless advantages such as design liberty, sustainability, and modification. This cutting-edge innovation is reshaping the future of fashion manufacturing, affecting supply chains, and driving market trends towards more effective and environment-friendly practices. As the market remains to progress, DTF printing will play an important role fit the way fabrics are generated and consumed in the years ahead.

From the ancient civilizations using methods like block printing to the electronic revolution of today, fabric printing has actually consistently pressed borders. As the craft spread to other components of the globe, new techniques such as display printing and roller printing Learn More arised throughout the Industrial Change, reinventing the textile sector.

The intro of electronic fabric printing in the late 20th century noted a significant shift towards even more versatile and lasting printing methods.With the development of textile printing methods from ancient methods like block printing to modern advancements such as electronic printing, the intro of Direct-to-Fabric (DTF) technology has substantially improved the effectiveness and sustainability of textile printing processes (DTF Printing).In feedback to the crucial change towards sustainability in fashion production, the adoption of innovative innovations like DTF printing not only addresses ecological concerns but likewise opens up avenues for unmatched layout flexibility and personalization in the textile sector

Report this page